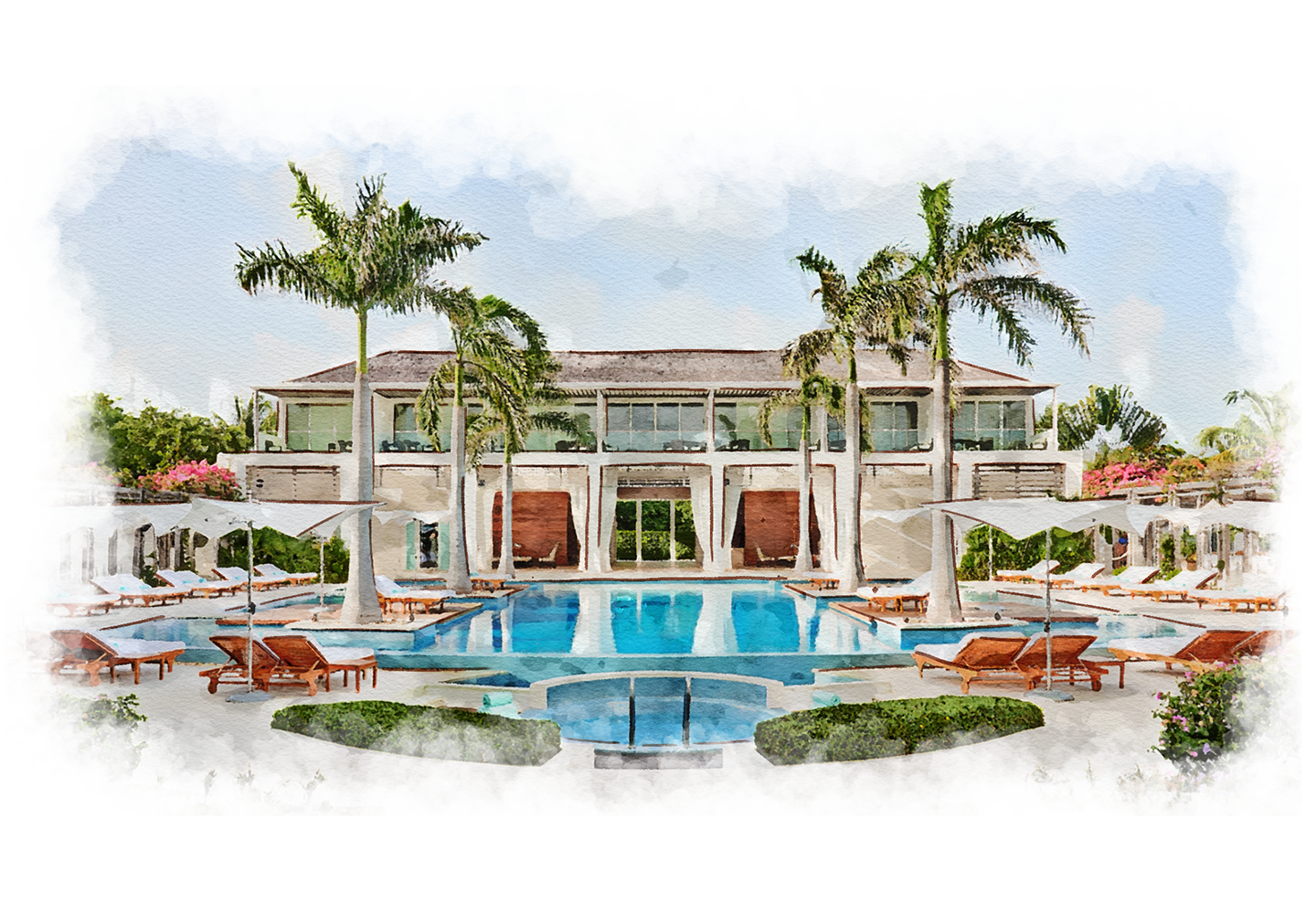

What's Hospitality Operations Software?

Everything you need for 100% perfect on-property operations in one integrated platform. Empower employees to make data-driven decisions, optimize housekeeping, eliminate service gaps, get ahead of preventative maintenance, boost productivity, align teams, and streamline communication. Our tech optimizes your teams by structuring them smartly — in alignment, not in silos. Plus, guest satisfaction will be bursting with our concierge component, giving guests access to the solution that offers access to everything in the area. Stop juggling on-property operations tasks, you’re not in the circus.

Solutions

Solutions

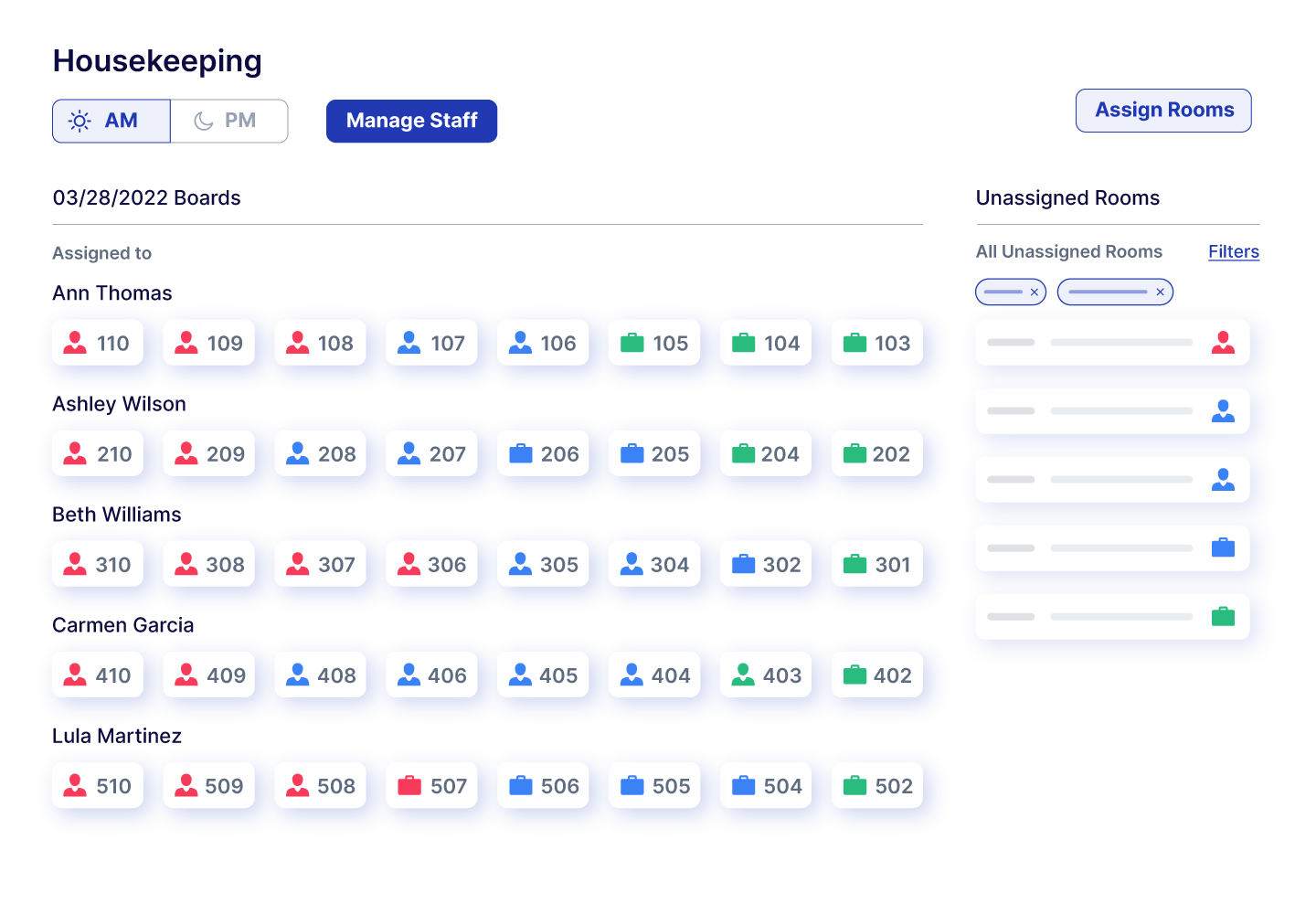

Housekeeping

Housekeeping

Increase staff productivity and decrease operating costs with features to improve communication and real-time room insights.

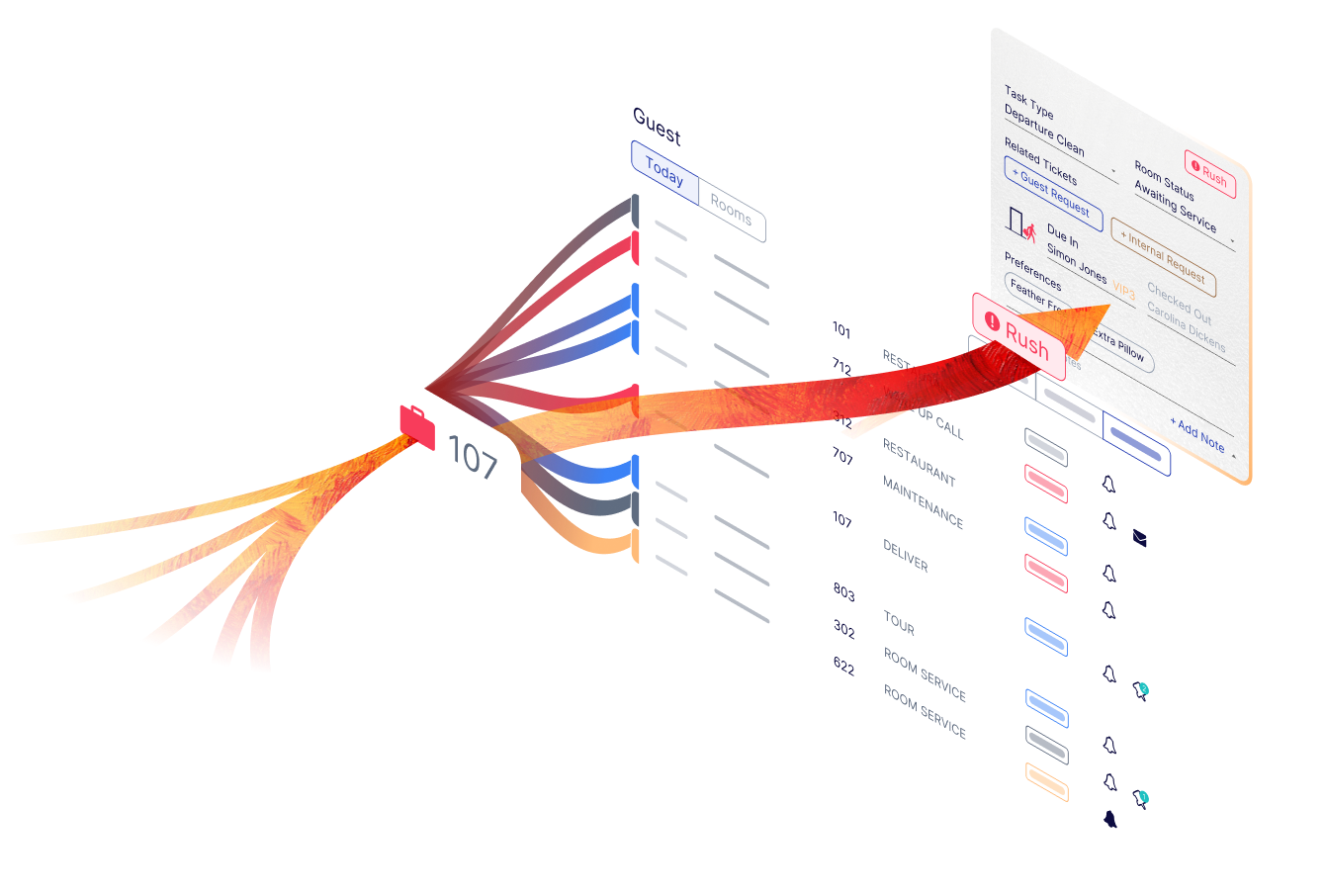

Service Delivery

Service Delivery

Help your staff work together to ensure guests' and team requests are met consistently and on time.

Guest Services & Concierge

Guest Services & Concierge

Equip your front desk to exceed guests' expectations with personalized services at scale.

Guest Messaging

Guest Messaging

Communicate with guests the way they prefer with real-time messaging.

Asset Management

Asset Management

Easily track and monitor your assets from a single dashboard, ensuring optimal performance.

CapEx Planning

CapEx Planning

Standardize, streamline, and add visibility to capital planning processes across your hotel portfolio.

Partner Testimonials

Integrations

Integrations matter. Actabl has the most. Over 270, to be exact. We make the integration work so you can see results quickly.